Mist Collectors

Installing a mist collector helps to keep your metalworking and industrial workplace safe, and increase your productivity while reducing costs from downtime. With today’s rising costs, you want to control your machining costs as much as possible. A good way to reduce coolant cost is to recycle the coolant back to your machine tool. Investing in oil mist collectors and mist collection systems in a machine shop is crucial for ensuring the health and safety of workers by reducing exposure to harmful airborne particles. It also helps in compliance with regulations, extends the lifespan of machinery, decreases the risk of fire hazards, enhances productivity and efficiency by providing a clean working environment, and demonstrates environmental responsibility by reducing air pollution. Overall, oil mist collectors protects both employees and the business itself while promoting sustainability and operational excellence.

Benefits of Oil Mist Collectors and Mist Collection Systems

Reduces:

- Exposure to harmful particles

- Risk of respiratory issues

- Costly downtime

Improves:

- Lifespan of machinery

- Environmental responsibility

- Compliance with regulations

Enhances:

- Productivity

- Reputation

- Cost savings

Coral Mist Collectors are used in all types of manual and CNC machine tools including:

- Grinders

- Machining Centers

- Screw Machines

- Milling Machines

- Lathes

- Swiss Style Turning Centers

- Rotary Transfer Machines

- Boring Mills

- Parts Washer

The Coral Noil is perfect for most types of applications. The Noil is designed for removal and recovery of water soluble mist and oil coolant mist in machine tool operations and industrial processes. The Noil uses three stages of filtration to eliminate mist from the workplace. The high speed turbine impeller is dynamically balanced and the second and third stage filter system does not rotate assuring vibration-free operation.

The design minimizes the amount of space needed for installation and the dimensional footprint takes up less space than other filtration equipment. With six sizes (<350 CFM – 1,530 CFM) to provide the perfect solution for every application and several different mounting options, the Noil can solve any air contaminant problems your shop may have. All Coral products carry CE approval. Electric motor is UL and CSA approved. Prices starting as low as $2,237.00.

A Post Filter Kit or HEPA Post Filter Kit can be used when a greater degree of filtration is required. Adding the Post Filter to the Noil Mist Collector adds a fourth stage of filtration. The Post Filter is a high efficiency filter and traps ultra fine particulate matter and returns clean air back into the work area. This ensures the work environment is free from contaminated air.

Why Noil Mist Collectors?

- No Vibration: Specifically designed to be vibration-free, an important advantage when you are machining precision parts

- Lower plant maintenance costs: Extremely long life filters reduce the need for frequent cleaning and filter replacement

- Increased productivity: By reducing the frequency of filter maintenance, you greatly reduce the need to stop machine production for routine housekeeping

- Sized for your application: Six models available to better suit your application, ranging from 350-1,530 CFM

- Energy efficient and quiet: The Coral Noil is energy efficient and is quiet to operate

- Versatile: Compact design with various mounting options.

- 40-day performance pledge: If the Noil does not perform as intended, return it for invoice credit. View our Performance Pledge »

- Best value: Competitively priced with a full 5 year warranty, including motor, and the best customer service in the industry

| Model | Max Air Flow (CFM) | Static Pressure (Inches) | Motor 220/440V 60Hz | 3400RPM HP | Weight (lbs) | Noise Level (dBA) |

|---|---|---|---|---|---|

| NOIL 06 | 350 | 2″ | 1 | 62 | 68 |

| NOIL 08 | 470 | 2″ | 1 | 64 | 72 |

| NOIL 12 | 700 | 2″ | 2 | 104 | 74 |

| NOIL 15 | 880 | 2″ | 2 | 108 | 75 |

| NOIL 20 | 1290 | 2″ | 2 | 114 | 75 |

| NOIL 26 | 1530 | 2″ | 3 | 120 | 76 |

Eliminate Mist With Three Stages Of Filtration

Stage 1

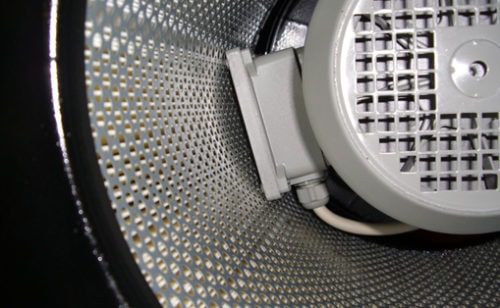

The first stage uses an impeller to convert the mist back to a liquid state and returns it to the machining process

Stage 2

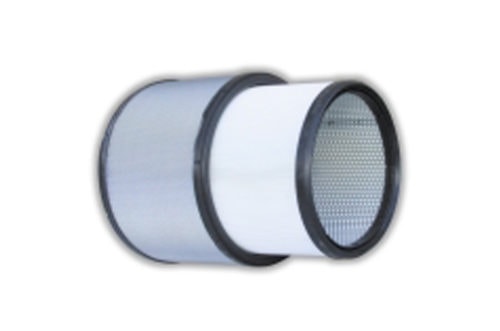

The second stage made of a dense cellulose filter cartridge removes finely aspirated particles

Stage 3

The third stage filter is a high efficiency polyester filter, rated 99.9% @ 2 micron particle size to remove all remaining particles

The Oil Stop Series

The Oil Stop

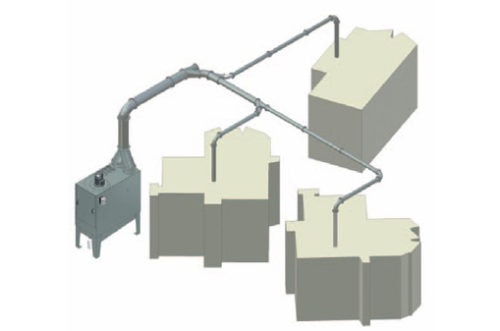

The Coral Oil Stop series is specifically designed for multiple machine tool applications to efficiently remove water soluble coolant mist, straight oil coolant mist and smoke to filter the air during machine tool operations. The Oil Stop is very productive and efficient utilizing three stages of filtration to eliminate mist and reclaim oil from the workplace achieving over 99% filtering efficiency. Models are available with a throughput from <774 CFM to 2,120 CFM.

The Oil Stop M

The next series up from the Coral Model Oil Stop is the Coral Model Oil Stop “M”, a high efficiency mist collector/air filter also designed for multiple machine tool applications. During machine tool operations the Oil Stop M removes water-soluble coolant mist, straight oil coolant mist and smoke. The Oil Stop M is manufactured with galvanized steel for a high resistance to corrosion, requires low maintenance and is extremely productive utilizing three stages of filtration to eliminate mist and reclaim oil from the workplace achieving a 99% filtering efficiency. Models are available with a throughput from <4,700 to 14,000 CFM.

*All specifications are subject to change without notice.