ITA, Inc. offers high-quality PTM Dead Centers to help machine shops reduce their production costs and improve efficiency.

PTM is a leading manufacturer of standard and custom-designed dead centers for turning and grinding applications. They are expertly crafted and manufactured with the highest quality materials available to ensure the best performance, highest accuracy, and longest life while keeping prices low.

PTM Dead Center Specifications

- Manufactured with the highest quality steel available

- Completely hardened and ground to 61-63 Rc for improved quality and long life

- Accuracy is guaranteed to +/- 0.001mm and +/-0.0015 mm for dead centers with an interchangeable point

- Holds tolerances that the competition can’t

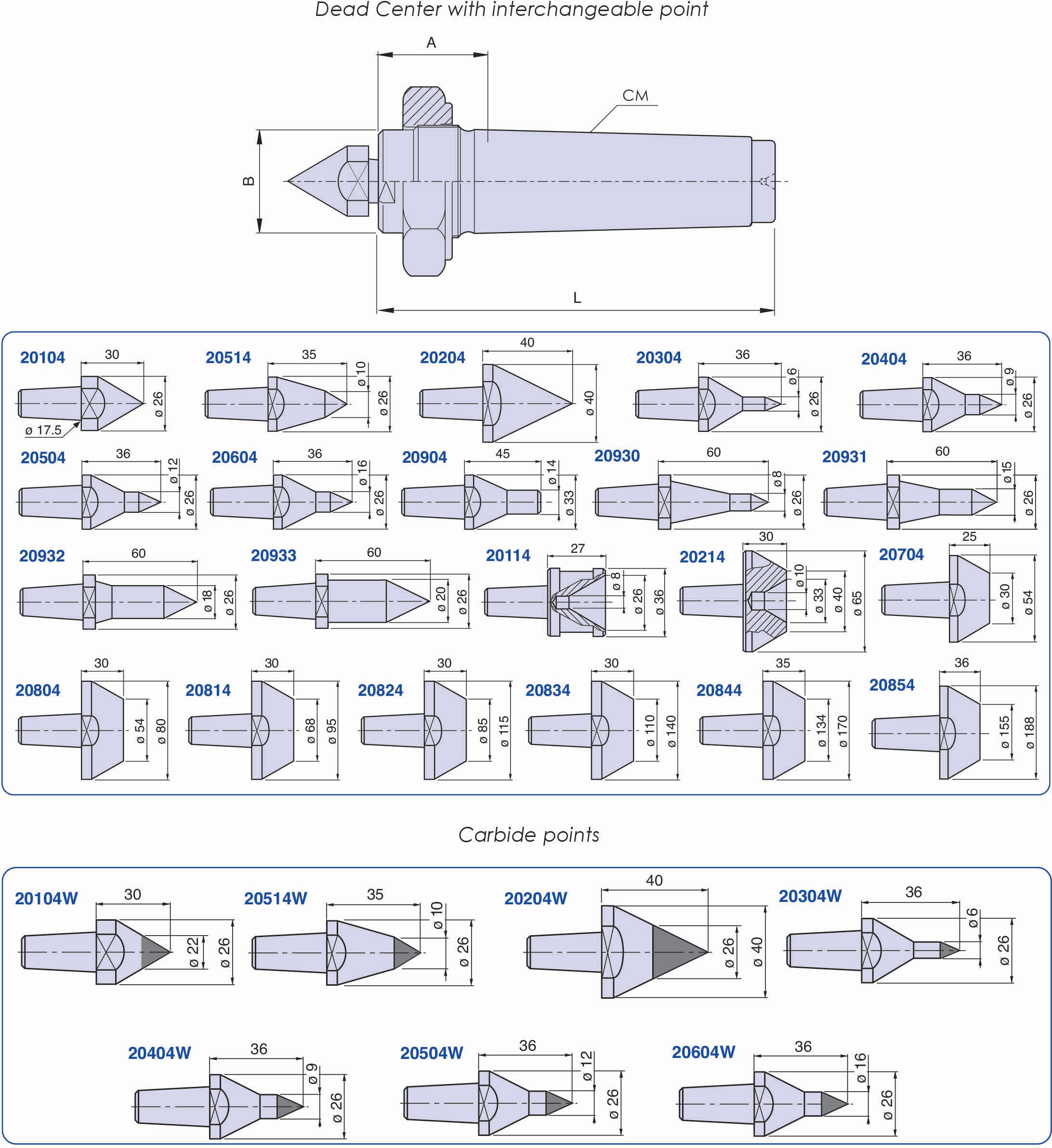

Interchangeable Points

To help you reduce your production costs and improve efficiency, many PTM dead centers are available with an extensive selection of interchangeable points for a variety of applications.

Carbide-Tipped Dead Centers

- Welded with the most advanced induction machines

- The strongest and most stable bond, guaranteed

- Fully hardened for the best combination of toughness and surface hardness

Dead Center Types Available

- Full dead centers

- Half dead centers

- Double pitch dead centers

- Bull nose dead centers

- Reduced point dead centers

- Dead centers for test benches

- Slotted dead centers

- Dead centers with & without carbide tips

- Interchangeable point dead centers

Custom Dead Centers

ITA also offers custom dead centers with quick turnaround and very reasonable prices to meet your specific requirements.

ITA’s Large Selection of Points for Live and Dead Centers Cuts Costs

Need help choosing the right dead center for your turning or grinding application? To speak with an ITA expert, call 410-777-8555 or contact us for more details today.

*All specifications are subject to change without notice.